Technology Connect

Experience | Assimilate | Demystify | Implement

Experience | Assimilate | Demystify | Implement

Adroit Control Engineers Private Limited is one of the known Electrical Control equipment manufacturer and Industrial Automation System Integrator in North India. The manufacturing of control equipment is engineered at 50000 Sq ft Manufacturing facility at Special Economic Zone (SEZ), Industrial Model Township (IMT) Faridabad, an industrial hub of Haryana, at the outskirts of Delhi.

From last 25 years Adroit as a manufacturer of Electrical Control Equipment and Industrial Automation system Integrator has not only lived up to the expectations of its customers but also delivered value by continuously transforming its manufacturing practices, standards and technologies for delivering value in a competitive capital goods sector.

Leverage Adroit’s 25+ years of Manufacturing and Industrial Automation System Integration expertise. Adroit can help any academic or Industrial institution looking to system integrate Industrial Automation system. Along with the System integration of the hardware, avail Adroit’s vast Industrial expertise, realization of any industrial application, workshops/Webinars customized and curated pedagogically for the academia.

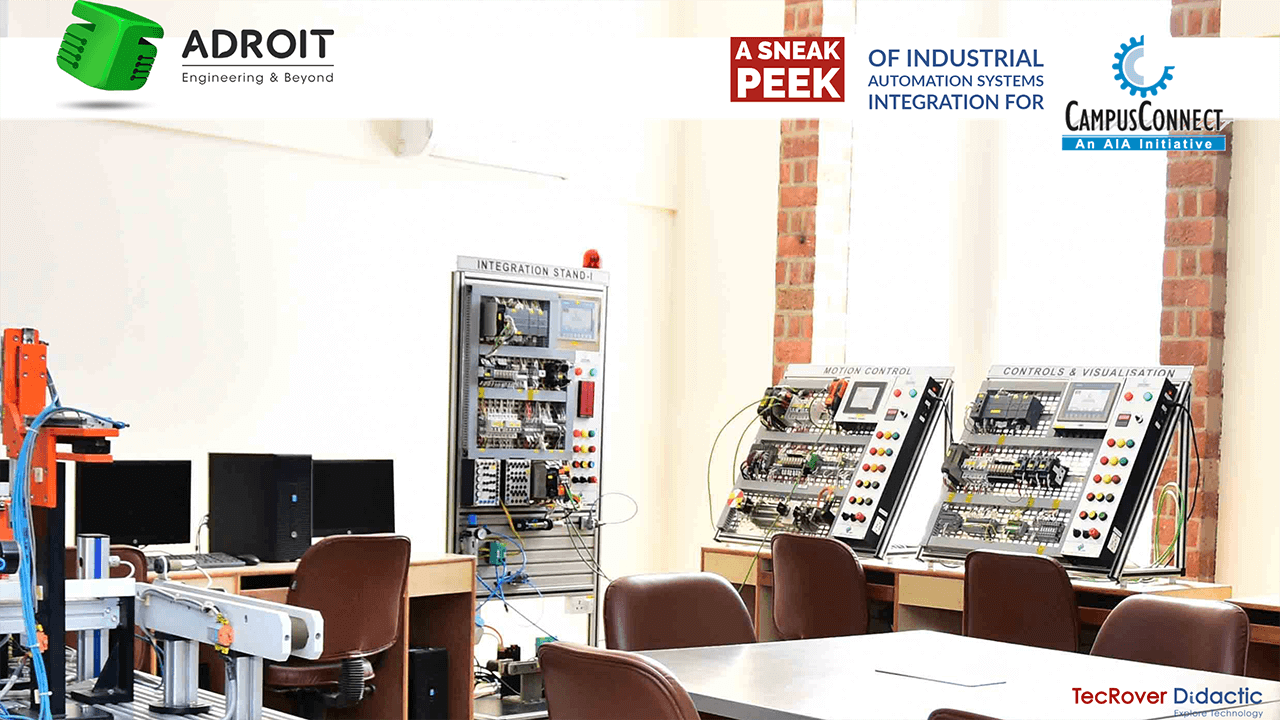

Industrial Automation Systems for Education

Designed under the aegis of Automation Industry Association for Campus Connect, a blended Learning Program, for chosen engineering colleges. The program imparts a holistic knowledge and experience in selection and use of modern automation technologies, integrating and programming them in different ways as per industry practices.

“The IEA (has estimated that 53 per cent of all electrical energy, or 10,500 TWh per year, is used by electric motor systems globally, giving rise to around 6,800 Mt of carbon dioxide (CO2) emissions (equivalent to the annual electricity generated by approximately 2,200 fossil fuel-fired power plants with a capacity of 1,000 MW.

Source:

United Nations Environment Programme

ENERGY-EFFICIENT ELECTRIC MOTORS AND MOTOR SYSTEMS

U4E-MotorGuide-201709-Final.pdf

“In India the industrial sector accounts for around 40% of the electricity demand, while the share from motor, and motor driven systems, consumption could be as high as 65% of the industrial electricity consumption.

Source:

https://open.unido.org/api/documents/4818324/download/Energy

Induction Motor Basics

Industrial applications often require precise control. In the past these applications relied on complicated gearing & clutches to control the speed of a given system

For Example

In applications like

Normally in commercial applications we are trying to achieve given flow and pressure. These variable change depending upon demand at any given time.

For Example

Some variable torque commercial applications can take advantage of affinity laws and use least amount of energy to meet the given flow or pressure demand.